HOLE PUNCHING

A convenient helper for transporting bottles!

Board with pre-punched holes is especially suitable as an intermediate layer for the transport of ampoules, bottles and components that have to be stabilised during transport on a pallet or inside cardboard packaging.

The holes punched from the greyboard are adjusted depending on the size of the goods to be stabilised and fix these just below their highest point. By fixing with punched board, sliding of the goods is minimised, contributing greatly to load security.

During the manufacture of the punch-out, the individual holes are punched from a raw sheet of board. Both the diameter of the holes and the spacing between them can be chosen freely.

We recommend additional rounding or chamfering of the board’s corners for intended use on a pallet in order to avoid tearing the film during stretch wrapping on the pallet.

Board with pre-punched holes is an ideal interlayer for transporting fragile and delicate goods, as the custom-made round holes in different diameters and spacings can be tailored to the goods to be transported.

Custom-made round holes in different diameters and spacings tailored to the goods to be transported.

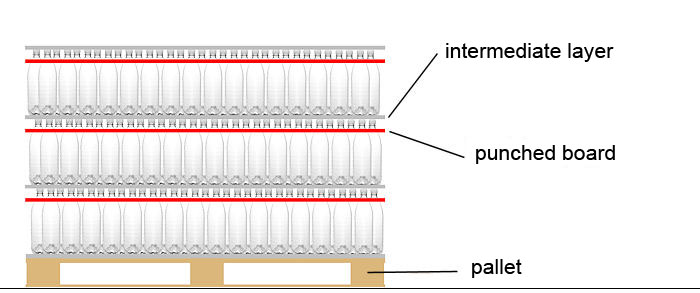

Sample application on a pallet:

Sample application: Punched board in combination with greyboard interlayers on a pallet with glass bottles.