CREASED AND GROOVED CUSTOM CUTS

For easy manual or machine processing!

Creasing and grooving are important preparations for processing into packaging, boxes, folding boxes and cartons. Creasing and grooving facilitate later assembly. The board can be bent easily along the creases, preventing tearing of the surface.

During grooving, so-called score lines and fold lines are created; these are later used as push-in flaps or retrieval openings during carton and box manufacture.

There is no weakening of the board material during creasing, rather, the material is displaced. Grooving, however, does weaken the material.

Available in the following grades:

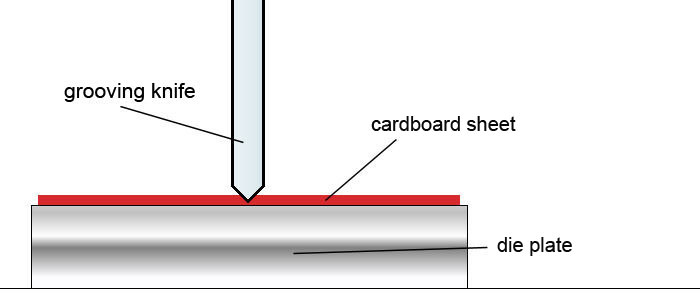

Grooving of the board:

During grooving, the outside of the board is cut with a sharp grooving tool (knife). Grooving leaves an elongated groove and with that, a folding or tear line. Pieces of the board can thus be levered out or bent.

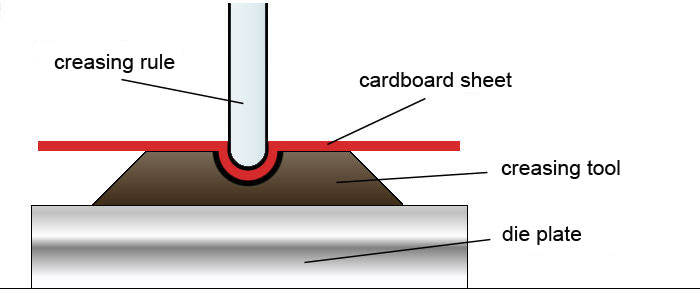

Creasing of the board:

Creasing causes a sculptural deformation of the material, caused by creasing rule and creasing groove. The crease’s thickness is determined by the upper tool’s width. The creased groove’s width in turn is determined by the width of the groove in the tool’s bottom part. During creasing, the board is put in a creasing matrix and pressed together with a pressing tool. Thus, an elevation and the actual crease, which will be the bending point during assembly, are created.